Piezoelectric nanogenerators with high performance against harsh conditions based on tunable N doped 4H-SiC nanowire arrays

Linlin Zhou, Tao Yang, Laipan Zhu, Weijun Li, Shuize Wang, Xinmei Hou, Xinping Mao, Zhong Lin Wang, Piezoelectric nanogenerators with high performance against harsh conditions based on tunable N doped 4H-SiC nanowire arrays, Nano Energy, 83, (2021), https://doi.org/10.1016/j.nanoen.2021.105826

In the context of global warming and the depletion of fossil energy, searching for new renewable energy sources has become an urgent problem. Mechanical energy including wind, vibration, etc. has attracted considerable attention for its wide distribution and high availability. Piezoelectric nanogenerators (PENG) have been proved to convert irregular mechanical energy into electricity. To date, various piezoelectric materials with great piezoelectric coefficients and superior energy conversion efficiencies have been used to assemble PENGs. However, most of the PENGs are often limited to serve at room temperature and neutral environment. With the development of the technology, the exploration of PENGs with the satisfying ability to work under harsh conditions, including high temperature and acid-base corrosive environment, is highly desired.

Recently, the "Green Metallurgy" research team led by Professor Hou Xinmei of University of Science and Technology Beijing published a research paper titled "Piezoelectric nanogenerators with high performance against harsh conditions based on tunable N doped 4H-SiC nanowire arrays", and proposed the piezoelectric nanogenerator against harsh conditions based on tunable N doped 4H-SiC nanowire arrays (NWAs). This paper was published at Nano Energy.

Figure 1 Schematic diagram of the service environment of the PENG based on N doped 4H-SiC NWAs

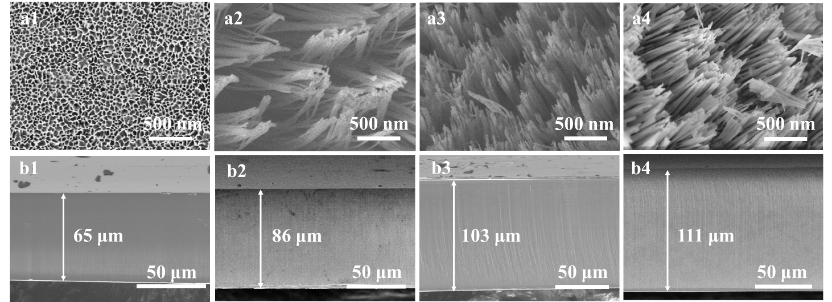

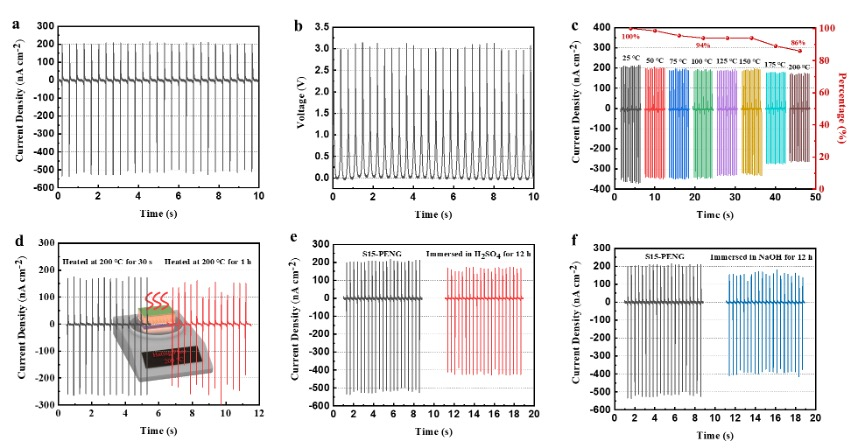

In this work, single-crystalline N doped 4H-SiC nanostructure arrays with different morphologies were obtained by anodic oxidation. When the anodizing time is 15 min, highly oriented NWAs can be obtained. The X-ray diffraction and transmission electron microscopy reveal that the as-resulted NWAs are pure 4H-SiC with high crystallinity. The freestanding single crystalline N doped 4H-SiC NWAs film was used to assemble PENG. The current density and voltage of the PENG at room temperature are 200 nA cm-2 and 3.0 V, respectively. The current density of the PENG at 100 ℃ (188 nA cm-2) and 200 ℃ (172 nA cm-2) is 94% and 86% of the current density measured at room temperature (25 ℃). And the output of the PENG heated at 200 ℃ for 1 h is 150 nA cm-2, which is 75% of the original output. The current density of PENG assembled by the NWAs soaked in H2SO4 for 12 h maintains 164 nA cm-2, and the output of the PENG packaged by another NWAs immersed in NaOH solution for 12 h reaches 155 nA cm-2. The PENGs still keep 82% and 77.5% of the initial output after being dipped in H2SO4 and NaOH.

The high performance of PENG based on tunable N doped 4H-SiC NWAs could be mainly attributed to the following points: i) The intrinsic properties of SiC. 4H-SiC with a wide band gap can accommodate more thermally excited electrons, so that it can operate normally in a high temperature environment. Besides, the robust physical and chemical inertness of SiC leads to excellent cyclic service stability and great acid-base resistance; ii) Quasi-aligned 1D single crystalline 4H-SiC NWAs. Once the vertically aligned NWAs are subjected to an external force, the 4H-SiC charge center will be relatively displaced to create a dipole moment. The sum of all the dipole moments in the NWAs produces a macroscopic piezoelectric field. And the voids between the NWAs provide space for the volume expansion of 4H-SiC nanowires, guaranteeing the structural stability of NWAs in a high-temperature environment; iii) The incorporated N-dopants. The dipoles formed by the introduction of N ions emerge directional polarization under force field, significantly enhancing the piezoelectric effect of 4H-SiC.

Figure 2 The typical SEM images of N doped 4H-SiC nanostructure arrays obtained by anodic oxidation with different times: (a1) and (b1) 11 min,(a2) and (b2) 15 min,(a3) and (b3) 18 min,(a4) and (b4) 21 min.

Figure 3 Performance test of the PENG based on N doped 4H-SiC NWAs in ordinary and extreme environments: (a) current, (b) voltage, (c) instantaneous high temperature, (d) long-term high temperature, (e) H2SO4 solution, (f) NaOH solution.

The "Green Metallurgy" team of the University of Science and Technology Beijing Iron and Steel Generic Technology Collaborative Innovation Center is based on the theoretical basis of metallurgical physics and chemistry, breaking through the limitations of traditional metallurgy, chemical industry, energy, environment and materials, and exploring the effects of new materials in the fields of steel, energy and environment. enhancement. The main research directions of the echelon include: (1) interface reaction kinetics; (2) research on the boundary wettability of high-temperature solutions; (3) development of new high-temperature ceramic materials; (4) metallurgical process wastewater, waste liquid, flue gas and solid waste Governance and comprehensive utilization; (5) Development of new optoelectronic and power-electric functional materials and device construction, etc.; (6) Multi-structure control of functional materials based on electrochemical metallurgy. Currently, there are 3 Professors (including 1 National Distinguished Young Scholars), 1 Associate Researchers, and 1 Assistant Researcher. The team has undertaken more than 20 national, provincial and ministerial projects, published more than 200 SCI papers, applied for more than 30 patents, and won more than 10 provincial and ministerial awards.

The research group of professor Xinmei Hou

The research group of professor Zhangfu Yuan